Need to know how to measure your rubber track size? Here is your guide, courtesy of Prowler Tracks MFG.

The rubber track manufacturer’s industry standard for identifying rubber tracks is a formula of:

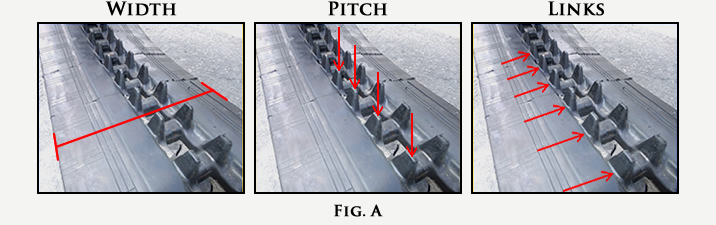

Width “x” Pitch “x” Links. (fig. A)

- Width = The width in millimeters of the rubber track

- Pitch = The center to center distance of the drive lugs

- Links = The number of drive lugs

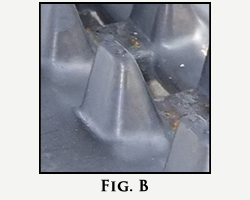

Several full size Excavators, Mini-Excavators, and Compact Track Loaders use metal core rubber tracks, sometimes referred to as steel core. This type of track utilizes a rubber carcass with embedded steel plates and steel cables that make up the skeleton of the track providing maximum durability and rigidity. The steel embedded plates protrude from the inner-center of the track to make up your Drive Lugs also known as “Wing guides”. (fig. B)

Several full size Excavators, Mini-Excavators, and Compact Track Loaders use metal core rubber tracks, sometimes referred to as steel core. This type of track utilizes a rubber carcass with embedded steel plates and steel cables that make up the skeleton of the track providing maximum durability and rigidity. The steel embedded plates protrude from the inner-center of the track to make up your Drive Lugs also known as “Wing guides”. (fig. B)

The other style of modern rubber tracks is a non-metal core, which is used on Multi-Terrain Loaders from ASV, CAT and Terex as well as agricultural Tractors such as the Cat Challenger and similar models available from John Deere and Case. The track measuring formula also works for this style of machines as well, with the pitch being the distance between rubber drive lugs rather than metal drive lugs. Measuring for identification on these machines is usually not an issue, as non-metal core tracks of this day and age are very model specific, so interchangeability is not an issue.

A common metal core track size is 450x86x55, which fits both the Bobcat T250 and T300 compact track loader. According to our formula, we know the following:

- Width = 450mm

- Pitch = 86mm

- Links = 55

If you multiply the Pitch times the total number of Links the result equals the total inner circumference of the track. (i.e. Pitch x Links = Circumference)

If you have a steel core track that you do not know the size of, you can easily work backwards to figure it out. Measure the width in inches or millimeters, measure the distance of two drive lugs center to center, and count the total number of drive lugs.

To convert millimeters to inches divide the total number of millimeters by 25.4. (i.e. 450mm / 25.4 = 17.71 or 18”)

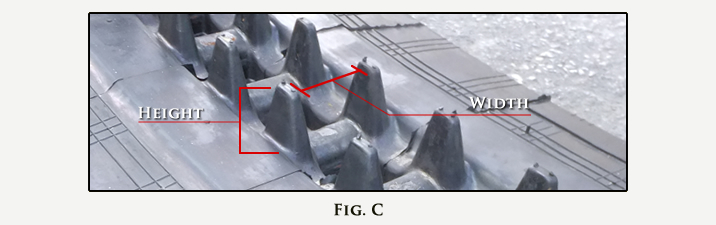

Another important identifying factor for steel core tracks is the inner and outer guide width, and guide height which has nomenclature generally specific to different manufacturers. This is often identified with an A, B, N, W, K, KW, or any other series of letters or numbers. (figure C) This is where you can run into problems when trying to interchange tracks. The inner and outer guide width and guide height should always be correct for your machine. This is so that the machine rides smoothly and does not “jump track” on uneven terrain or slopes, and so that your undercarriage does not fail prematurely. Inner and outer guide width measurements can be estimated from your old rubber track, but cannot be accurately ascertained because of wear unless they are obviously brand new.

The metal core rubber tracks that we stock at Prowler Tracks can have up 4 different guide styles. Keep in mind that it is to the advantage of a reseller to only stock certain sizes and guide widths, as they can be substituted for others, significantly cutting cost for that supplier. This is where you need to be careful. For example, at Prowler Tracks, we have three different 300×52.5×80 size rubber tracks because there are 3 different OEM designs for this particular size. A Kubota mini excavator model KX91, a Komatsu PC30, and an IHI 30J mini excavator all use a 300×52.5×80 track. Theoretically, one of these tracks could be stocked and used on all 3 models, which is what many suppliers may do. The above measurements, while correct, do not account for the differences in guide sizes, particularly guide height, including inner and outer guide widths. If you have ever had a new track that you knew was the right size, but just wouldn’t stay on, or was eating away at your sprockets or rollers, or rode so rough it rattled the windows out of your machine, this is the most likely reason.

In summary, it is a fairly simple operation to establish your track size. However, it is also important not to assume a used rubber track off your buddy’s machine, an odd rubber track you may see online for sale, or an interchangeable rubber track from a discounter will fit your machine. You need to work with a rubber track supplier that you can count on to give you proper information needed to accurately fit your machine with the right sized track. If you are wondering about your rubber track options, or even wondering if that spare rubber track off your buddy’s Cat 302.5 mini excavator will fit on your Bobcat 325, give us a call at Prowler Rubber Tracks at 877-477-6953 or check us out at our online store ProwlerMFG.com

ShareMAR

2014

About the Author:

Todd Swift - Sales Manager at Prowler Tracks